Intelligent Welding Automation

Industry 4.0

Data is the engine that will drive adoption of Industry 4.0, an industrial revolution for automating production and producing better products. Yet several factors prevent manufacturers from fully exploiting operational data.

IT&OT=MOM

Traditional operational technology (OT) architectures tend to be monolithic and difficult to upgrade. And although today’s production machines generate terabyte-class volumes of IoT sensor data, it often remains siloed in non-standard formats. In addition, analytical insights require OT to be integrated with IT systems such as enterprise resource planning (ERP) and product lifecycle management. Manufacturers may lack personnel for this work.

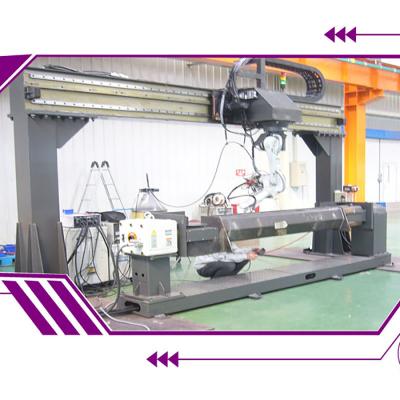

Start welding automation1993

1993year ,start welding machine

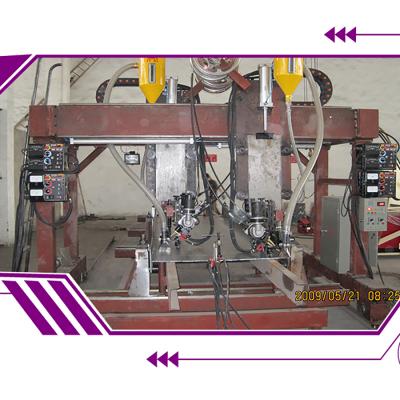

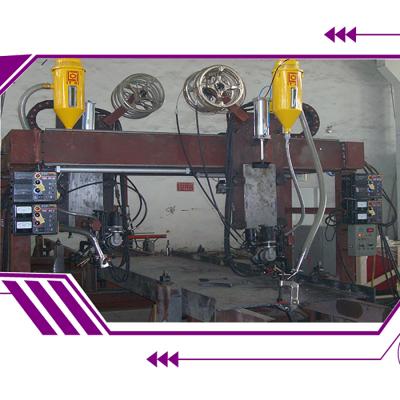

New plant for oversea 2005

2005year,start welding equipment overseas market

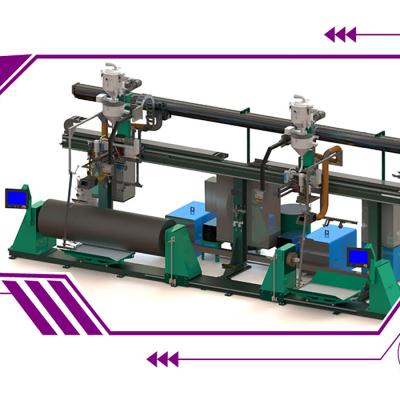

Digital intelligent product 2021

Digital intelligent upgrade of welding equipment will begin in 2021

Now the process of purchasing equipment is simple

Our Plant can exist in any urban environment via internet, just a short distance away from where you live and shop. This means we can deliver new produce within days, compared.